Reliability & Maintenance

We draw on our diverse mix of operational experiences in reliability and maintenance to understand where business value is generated. With this understanding, we are then able to work with your organisation to understand root causes of problems and to then develop and deliver improvements to the business, whilst transferring skills and knowledge to your internal teams helping to develop sustainability within your internal teams.

Typical ways we help

- A relentless focus on preventing the erosion of business value.

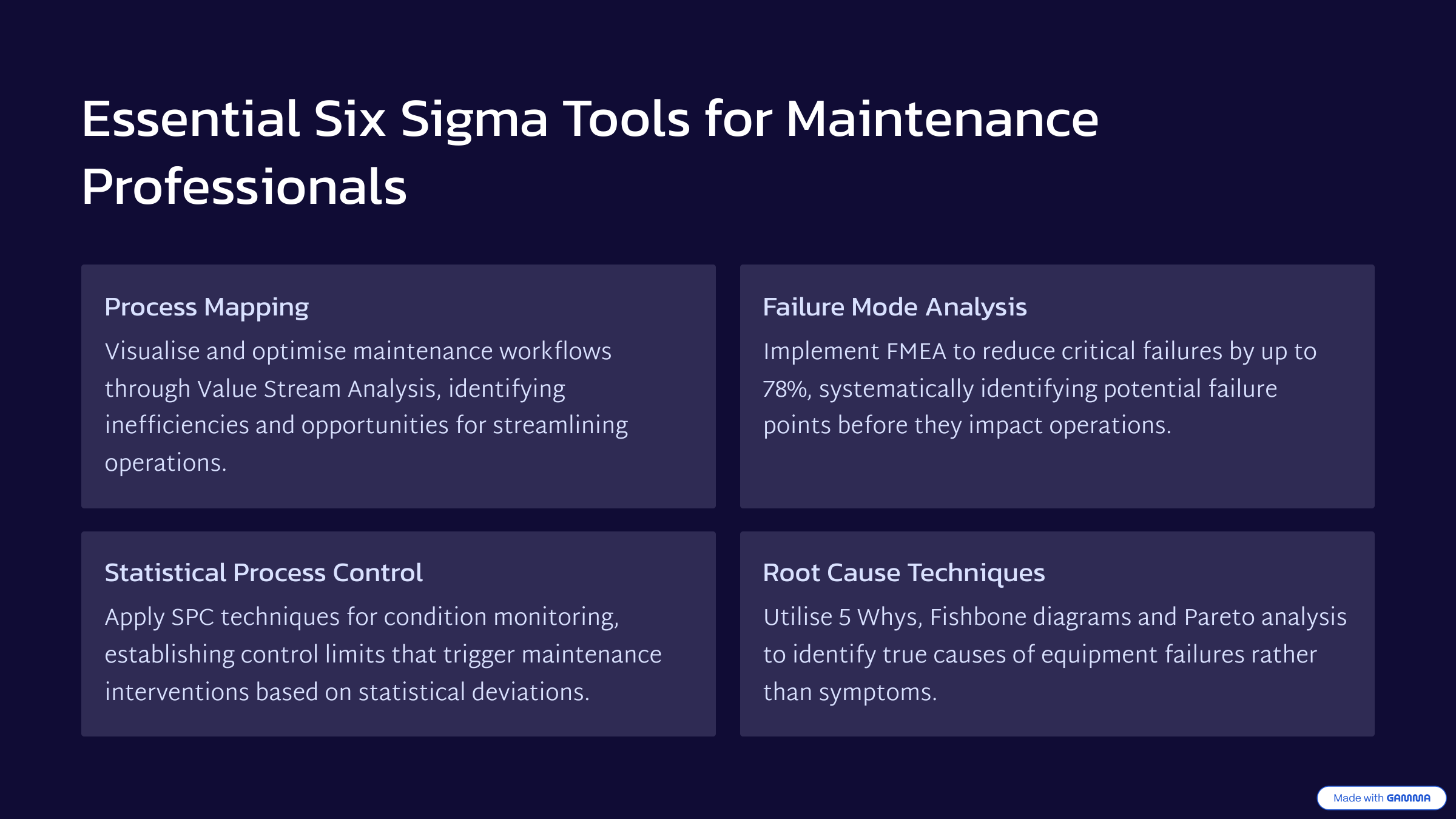

- Facilitation of rigorous Root Cause Analysis with proven techniques appropriate for the level of problem we are solving. This is completed cross-functional site teams.

- Development and implementation of action plans to reduce or prevent reoccurrence.

- A process to enable the effective identification of improvement opportunities.

- Understanding asset criticality using risk based methodologies.

- Analysis of Failure Modes and Effects (FMEA) and/or Reliability Centred Maintenance approaches.

- Development of reliability strategies to reduce maintenance costs.

- Development of online maintenance dashboards for maintenance staff.

- Developing, implementing and then optimising maintenance tactics – i.e. routine tasks to address functional failures

- The right people, doing the right work at the right time, to ultimately improve and sustain asset reliability and availability

- Optimising critical spares holdings

- Improving the management of hydrocarbons, to reduce operating costs, prevent equipment failures and plant downtime – considers product cleanliness, handling, storage, dispensing, analysis and management practices

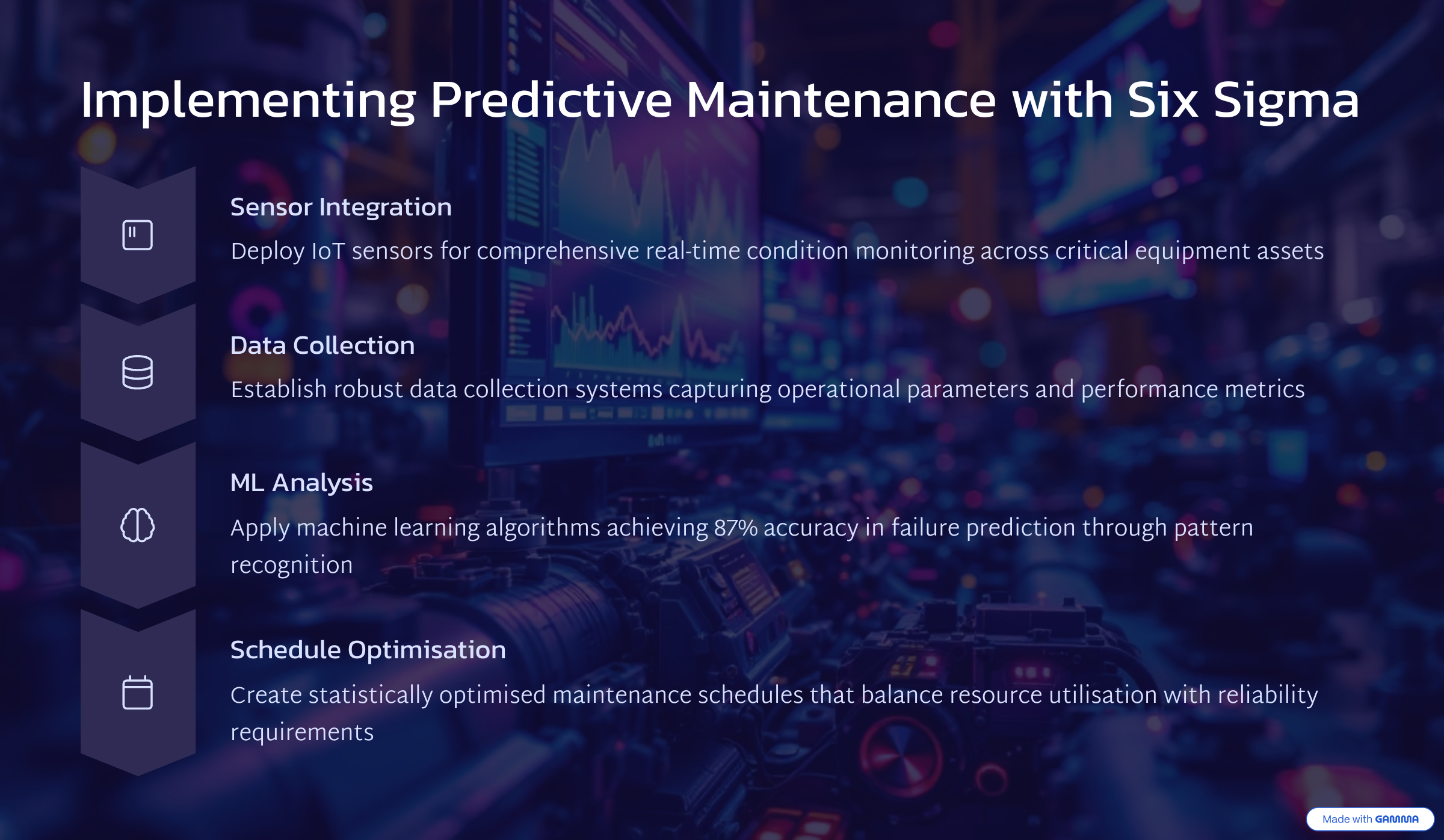

- Implementation of condition-based predictive maintenance tactics for both mobile and fixed plant assets using specialised techniques and instrumentation to measure and monitor the health of equipment components throughout their life

- Complete integration of asset health data into online systems, including consideration of the people and process aspects

Six Sigma Reliability and Maintenance: Optimising Asset Performance

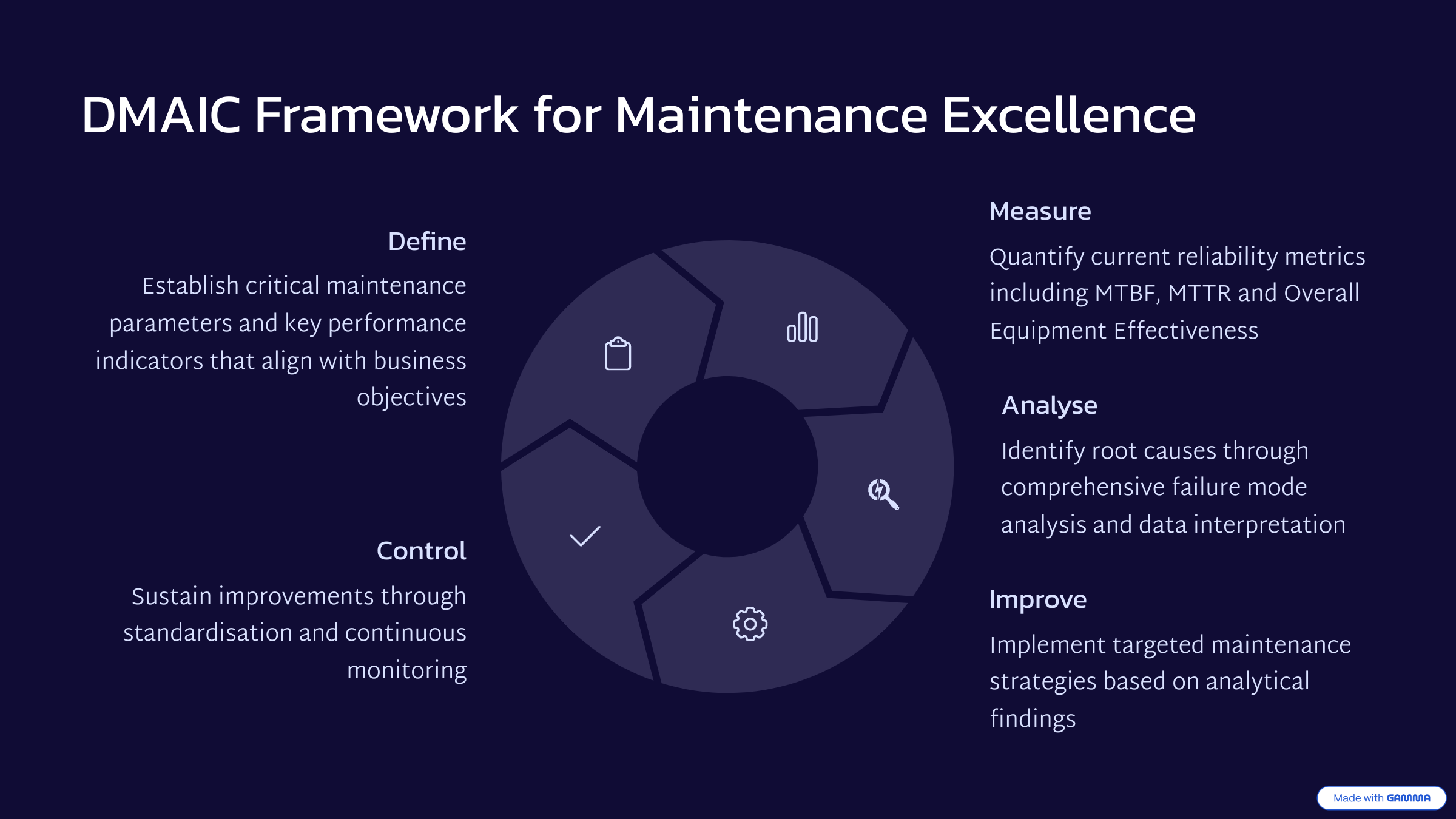

A comprehensive methodology reducing defects to just 3.4 per million opportunities. With 47% of large UK enterprises implementing Six Sigma, organisations are achieving 35-65% reductions in downtime through the DMAIC framework (Define-Measure-Analyse-Improve-Control).

Understanding Six Sigma in the Maintenance Context

Statistical Excellence

Six Sigma targets 99.99966% defect-free processes, representing a statistical approach to maintenance perfection that unlocks £4.2 billion in annual savings potential across UK industrial maintenance operations.

Evolution

From its origins in manufacturing quality, Six Sigma has evolved into a comprehensive maintenance excellence framework that integrates seamlessly with existing ISO 55000 Asset Management standards.

Transformation

The Six Sigma approach transforms traditional reactive maintenance into proactive, data-driven strategies that significantly enhance equipment reliability and operational efficiency.